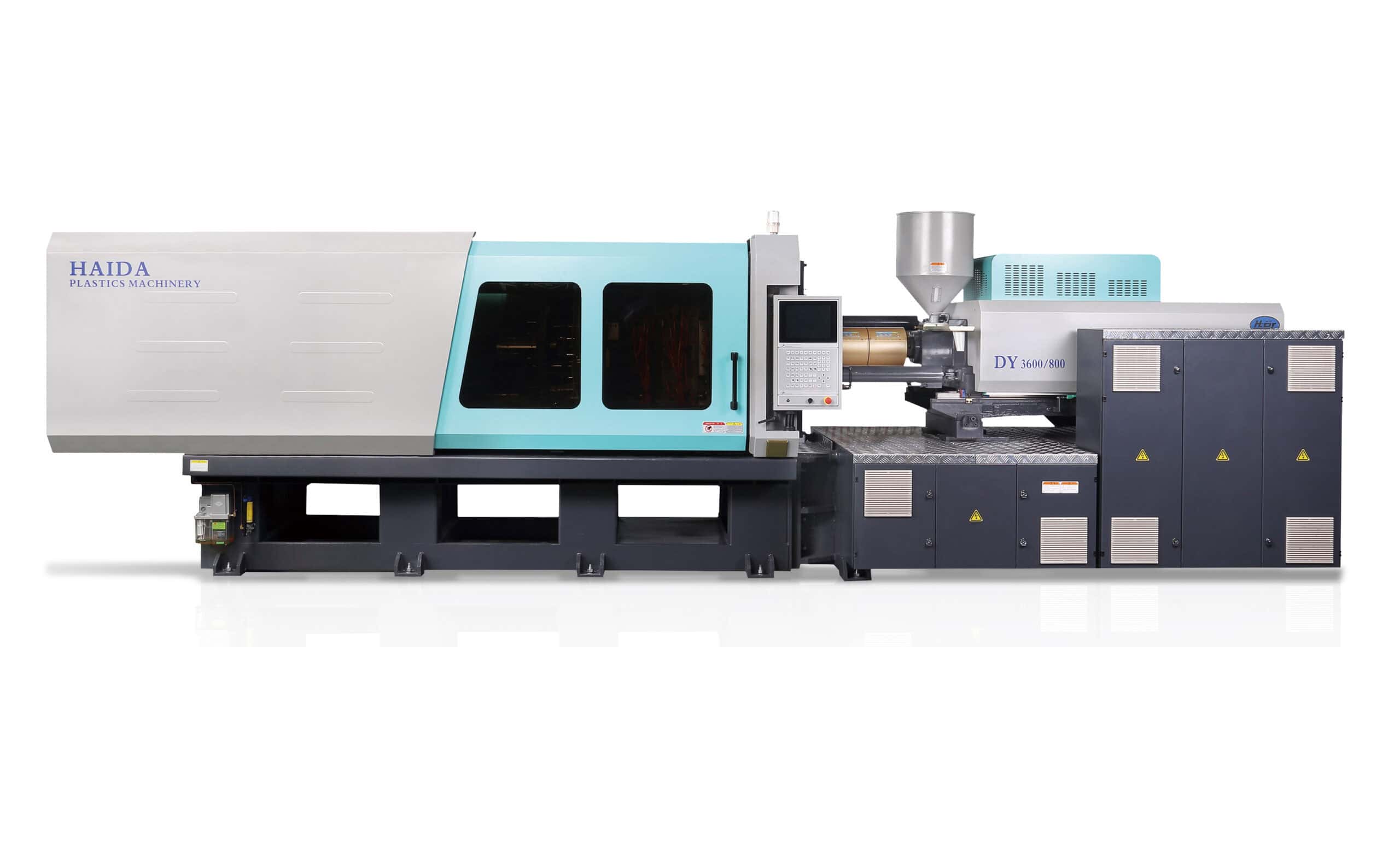

DETAIL & FEATURE

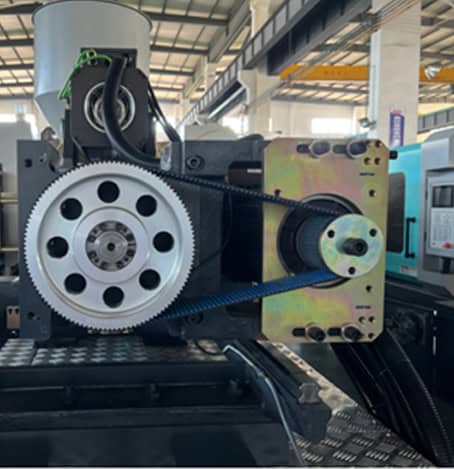

INJECTION SYSTEM

Charging and injection are directly driven by servo motor. System with ball-screw of famous foreign brands and special axial bearing ensure precise and efficient ejection device. Injection pressure sensor has strong anti-interference and high resolution. Full hard steel alloy screw has high strength, good corrosion resistance and longer service life. Professional self-lubrication system, apply high pressure/heat/water-resistant high-performance lubricating grease for injection ball screw. Reserved plastic bearing and synchronous pulley bearing, and high load-carrying capacity can extend service life of the machine.

HIGH PRECISION

Oil-Electric composite molding machine has maximum precision. It has truly realized high precision and high repeatability full-closed loop control by using full-closed loop composite operation of pressure, flow, and position control.

IMPROVE PRODUCTION EFFICIENCY

Rapid Response, High Production Efficiency; High Repetition Accuracy, Save Raw Materials.

OUTSTANDING ENERGY-SAVING

Power saving: motor doesn't work during cooling stage; thus, power consumption is 0. Water-oil saving: compared to traditional hydraulic power system, reduce 1/4~1/3 of hydraulic oil consumption; may omit cooling, thus save a large amount of water.

LONGER SERVICE LIFE,

CLEAR WORKING ENVIRONMENT

Less Noise Emission: control noise of hydraulic system within national standard scope. Lower energy requirements for waste heat and cooling, more suitable for production environment with air conditioner: from boot to steady state of injection machine, the rise of oil temperature is about 8 -10 degree.

HYDRAULIC SYSTEM

Adopt high-performance hydraulic components of famous international brands and use efficient energy-saving hydraulic servo system for clamping, ejection, corn and platen adjustment, etc. with sophisticated and complete corn and un-screwing functions. It can realize linkage clamping and charging and shorten molding cycle. Perfect combination of servo motor and internal gear pump and closed-loop control that formed through high precision sensors has greatly improved equipment precision. Use optional clamping proportional directional valve to realize higher position precision and quicker response.

APPLICATIONS

APPLICATION CASES

COMPANY PROFILE

Ningbo Haida Plastic Machinery Co., Ltd is a manufacture specialized in manufacturing HAIDA series automatic plastic injection molding machine,

vice president of China Plastic Machine Industry Association, and one of top 10 enterprises in plastic injection molding machine industry of China. The

company enjoys higher brand awareness in the industry. In recent years, the company has obtained various honors and awards, e.g. National High-tech

Enterprise, Famous Chinese Brand, Famous Brand of Zhejiang Province, Celebrated Products of Zhejiang Province, Well-known Trademark of Zhejiang

Province, and Work Safety Standard Enterprise of Zhejiang Province, etc. In 2000, the company has obtained self-support import and export right,

and has registered brand in dozens of nations and regions around the world. In terms of management, the company has passed ISO9001, ISO14001,

OHSAS18001 and CE authentication. The company has implemented 5S management, PLM Product Lifecycle Management and ERP Enterprise

information management and obtained significant results.

Established in 1992, the company covers an area more than 200,000 square meters , with total assets of RMB 500 million Yuan, and about 500 employees; above 30% of employees are technicians with intermediate or senior professional titles, and famous senior experts and professors are invited regularly as technical consultant and management consultant. The company also cooperated with famous domestic universities to co-found research center, and has been devoted to development, production and sales of efficient, individual injection with high cost performance; launched injection machines include servo energy-saving injection machine, efficient high-performance precision injection machine, oil-electric hybrid injection machine, fully electric injection machine, two-platen injection machine, unmixed two color injection machine and mixed two color injection machine, etc.

The company has expand sales market, and has established more than 60 sales and service agencies at home and abroad, with sales performance

rinsing steadily.

RELEVANT RECOMMENDATION